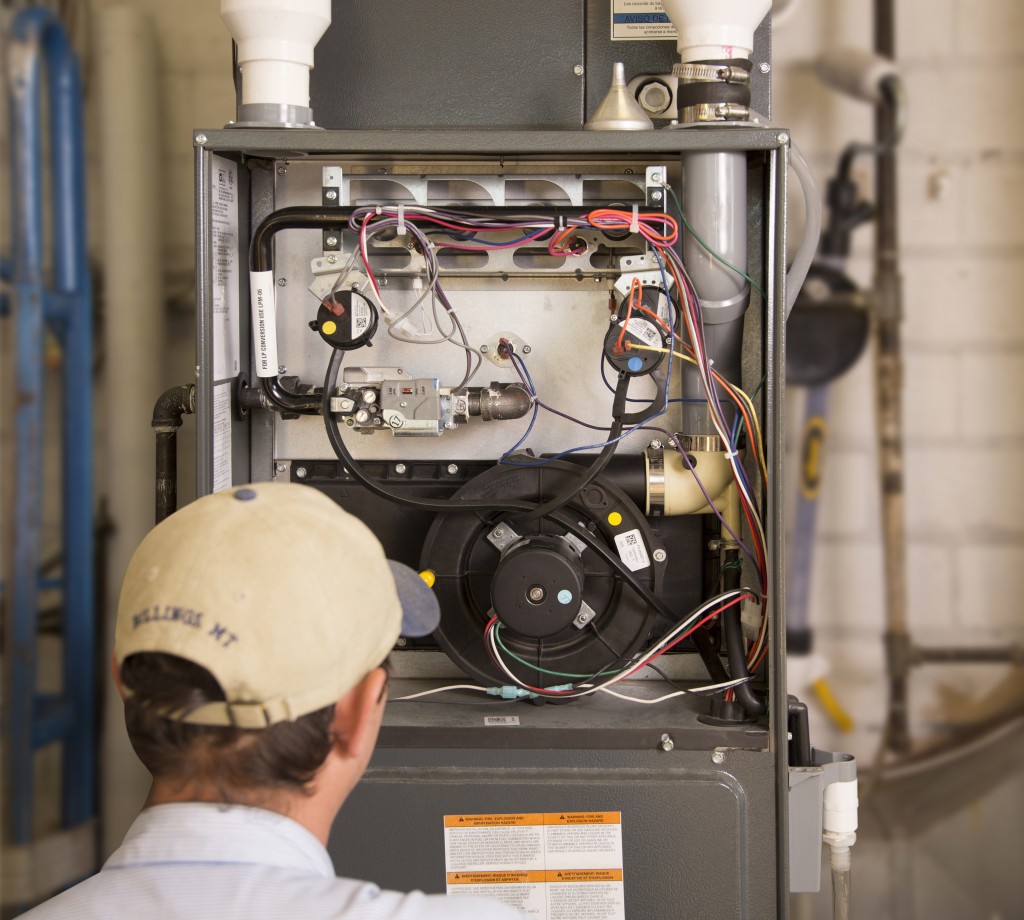

If you have a high efficiency condensing furnace installed at home then you should know that it is a little more complex compared to the traditional ones. The working is exceptional, but the problems surfacing from the high efficiency unit is also very different and needs to be handled professionally. These are known as condensing furnaces because of the second heat exchanger that extracts additional heat from the air passing through the first heat exchanger. This heat extraction process cause water vapor to condense out of the air which is drained through a tube placed in a floor drain. It is easy to identify this high-efficiency furnace through this drainage tube.

Even if these are high-efficiency furnaces, these are not devoid of issues. You would need to get in touch with a technician for furnace repair in Queens if you face any issue with these furnaces.

What are the common issues that you can face with these furnace?

The common issue with a condensing furnace is when it gives out a weak flame or does not ignite at all. There are some conditions why that happens. Following are the areas of concern:

Furnace repair for obstructed intake air vent

An obstructed air intake vent pipe in a direct-vent two-pipe system that can cause combustion issues in a condensing furnace. One needs to first check whether the issue is resulting from the obstructed air supply pipe by removing the burner compartment cover. This will lead to free airflow to the combustion chamber. After doing this if the combustion improves, then most likely the dedicated combustion air supply vent pipe has obstruction. Obstructions can be caused due to birds nests or leaves in the air intake vent. This vent needs to be cleaned to do away with future hassles.

Improper exhaust gas re-circulation

This problem gives rise to a weak flame or ignition problem when the direct-vent system has the air intake and exhaust vents installed improperly. This can cause short-circuiting allowing the exhaust gases to flow back into the combustion air intake pipe. The cause of this is the close placement of the air intake and exhaust vents. The problem can be solved with installing a concentric vent or separate vent pipes using a two-pipe system.

Clogged condensate drain

Ignition issues with a condensing furnace can also be due to a clogged flue vent condensate line. A partially clogged condensate line or a clog at the condensate collector box near the inducer fan can often lead to tripping the furnace’s pressure switch. Another sign of the clogged condensate drain line is when excessive water comes out of the drainage hole of the secondary heat exchanger when the drain line is disconnected. Ignition issues caused by this needs to be resolved. A technician offering furnace repair in Brooklyn needs to look into the problem as it gets repeated if the problem is not resolved.

Apart from these, a high-efficiency furnace can face other issues too. Being a complex equipment, it pays off not to handle things on own, and get the help of a professional instead.

Over 35 years of experienced HVAC engineer and blogger with years of experience writing about various topics related to multiple types of HVAC systems installation, repair, and maintenance. I have been in this industry since my apprenticeship in 1985. Our team emphasizes quality workmanship while ensuring customer satisfaction is our top priority.

Leave a Reply

You must be logged in to post a comment.